With the advent of 2 wheeler and 3 wheeler vehicles in the Indian market, the proportion of EVs on road is skewed towards low power low voltage segments. These segments consist of battery size of 2kWh to 7 kWh for a range of 60km to 200km. This results in a driving range of around 40km/kWh in 2 wheelers and 20km/kWh in 3 wheelers. This results in a home power plug of 15A limit offering a range increment of around 40km in 2 wheelers in 20km in 3 wheelers in just 20 minutes. However the issue is higher cost of the solution and higher packaging space making 3.3kW or 15A charger not part of standard offering. To take care of this, Nhanz decided to make a low cost, high power dense charger for the same power by reducing its size and weight.

Nhanz systems Private Limited is an MSME registered in India and based its office in Bengaluru, India. Nhanz was incepted in 2017 and was offering services to automotive and manufacturing firms inline to motor and other drivetrain components. In 2021, product development kickstarted to manufacture drivetrain components for Electric vehicles. Nhanz is currently moving into production of developed motor controllers, motors, gearboxes and chargers for low voltage and validating its high voltage offerings.

Main challenge was for a high power dense charger, typical semiconductors required were of high cost and moderate cost semiconductors resulted in very high packaging space. Also there was the need of high performance PCB laminates for carrying around 65A continuously during the charging operation at high ambient temperature. Tighter packaging space also meant higher interference between internal components which could cause crosstalk issues and EMC issues. To resolve this, Nhanz optimized the electrical and mechanical designs with SiWave and IcePack offerings from Ansys.

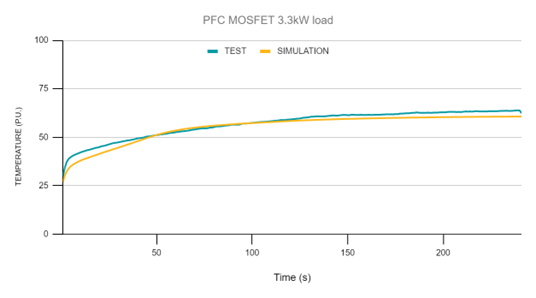

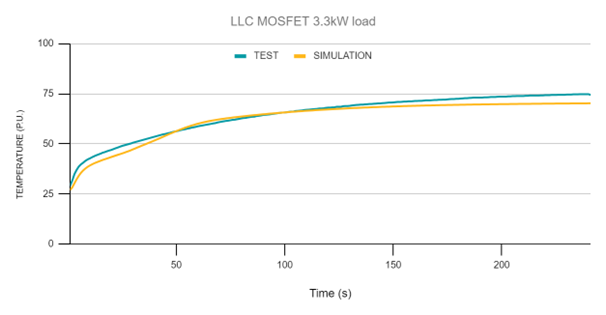

Nhanz needed to optimize the electrical and mechanical designs. They chose SIwave and Icepack offerings from Ansys. Key was to keep the product BOM cost low and meet the technical requirements. Hence, a virtual validation plan is made to prioritize the targets and execute simulations in SiWave, Q3D and Icepack. Here, heat generation elements position was iteratively finalized and detailed simulation was done to confirm product thermal performance targets are met. As the plan was to use lower copper thickness for the PCB for cost control, optimization was done in gerber to eliminate all hotspots.

Mr. Abhijith V P

Chief Technology Officer – Nhanz systems Private Limited