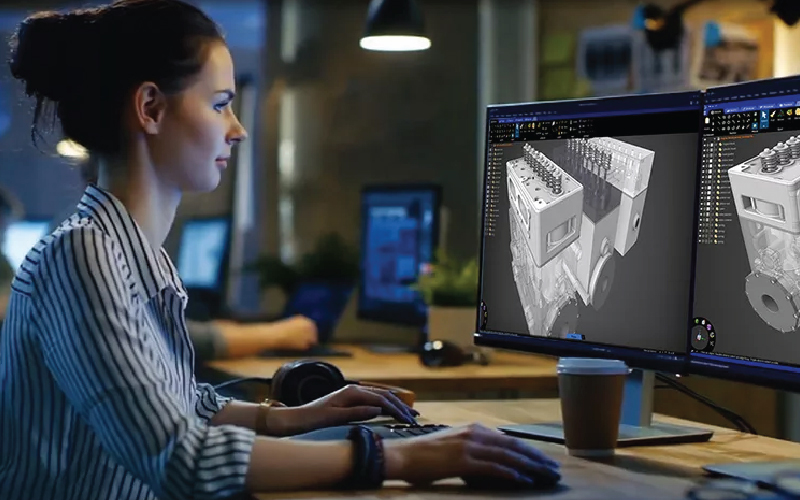

Chúng tôi cung cấp các dịch vụ thiết kế toàn diện nhằm thúc đẩy sự đổi mới và xuất sắc trong kỹ thuật. Đội ngũ chuyên gia của chúng tôi chuyên tạo ra các giải pháp tùy chỉnh để đáp ứng các yêu cầu cụ thể của dự án của bạn.

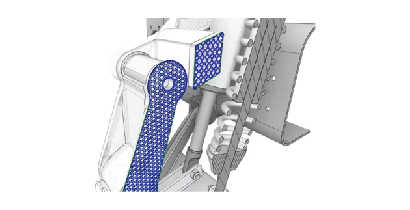

Các ý tưởng thiết kế giai đoạn đầu nhằm khám phá nhiều khả năng mà không có bất kỳ ràng buộc kỹ thuật nào và tối ưu hóa việc sắp xếp/tích hợp các thành phần lắp ráp trong một hệ thống/sản phẩm.

Concept design services is the creative phase in engineering projects where ideas are generated, nurtured, and evaluated without technical constraints. It’s where innovative solutions are envisioned and refined for specific challenges. This phase involves ideation, sketching, feasibility analysis, and iterative refinement to lay the foundation for the project. On the other hand, package studies focus on optimizing component arrangement and integration in systems or products to ensure efficient use of space, minimize wastage, and enhance performance, crucial in industries like automotive, aerospace, and consumer electronics. Key aspects include spatial layout, integration, ergonomics, and simulation.

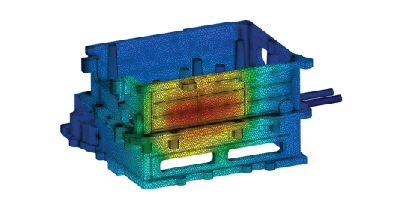

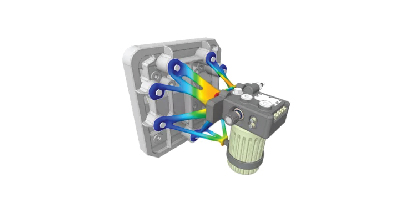

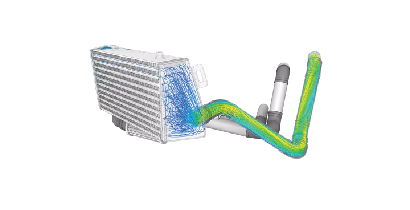

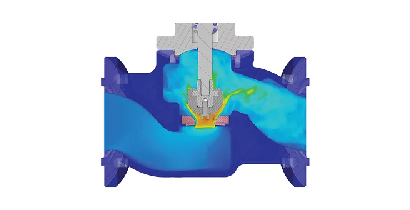

Three-dimensional Computer-Aided Design (3D CAD) modeling is essential in modern engineering,

Enabling the creation of digital representations of physical objects for analysis, visualization, and manufacturing. The process followed in design services involves several steps: conceptualization, sketching, extrusion and revolving, detailing and feature creation, parametric modeling, and validation and verification. In engineering, assemblies are collections of individual components combined to form a complete system or product. 3D CAD assemblies help engineers visualize how components fit together and interact. The process includes component modeling, assembly creation, motion simulation, interference detection, and Bill of Materials (BOM) generation.

Reverse engineering is the process of analyzing a product, component, or system to understand its structure, functionality, and design principles.

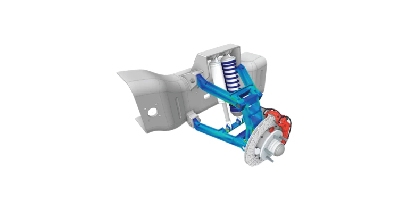

Giao tiếp bằng ngôn ngữ biểu tượng giữa các nhóm chức năng chéo và hiểu các biến thể bằng cách sử dụng phân tích xếp chồng dung sai

Geometric Dimensioning and Tolerancing (GD&T) and stack-up analysis are vital in engineering design services for ensuring proper function and assembly of mechanical systems. GD&T, a symbolic language, communicates design specifications precisely, ensuring interchangeability and functionality. Stack-up analysis predicts cumulative dimensional variation, considering component tolerances and assembly processes. Both practices promote clear communication among designers, manufacturers, and quality control, ensuring parts meet specifications reliably.

Chuyển đổi bản vẽ 2D của các đối tượng thành các mô hình kỹ thuật số đa chiều

Converting 2D drawings or sketches into 3D models is crucial in engineering and design services for visualizing concepts, prototyping, and manufacturing. This process involves transforming flat representations into fully dimensional digital models. The steps include choosing modeling software, importing or tracing, using techniques like extrusion and lofting, detailing with filleting, applying parametric modeling, and then adding dimensions, annotations, GD&T, surface finishes, assembly considerations, and finally, reviewing and documenting the 3D model.

Đánh giá và thực hiện các sửa đổi thiết kế để phù hợp với yêu cầu sản phẩm

Design modifications in design services are changes made to an existing product, system, or structure to enhance its performance, functionality, efficiency, or aesthetics. These changes can be driven by factors like evolving requirements, technological advancements, customer feedback, or the need to address issues found during testing or use. A structured approach to handling design modifications involves identifying the need, defining objectives, evaluating alternatives, conceptualizing and designing the changes, conducting analysis and testing, implementing the modifications, validating and verifying them, and finally, documenting and communicating the changes.

Hướng dẫn bản vẽ nguyên mẫu để chế tạo nguyên mẫu vật lý trong khái niệm thiết kế

Creating prototype drawings is a pivotal step in product development, guiding the fabrication of physical prototypes. A structured approach involves defining scope and objectives, gathering design information, determining prototype components, creating assembly and part drawings, adding annotations, reviewing and revising, finalizing documentation, and distributing it for communication.