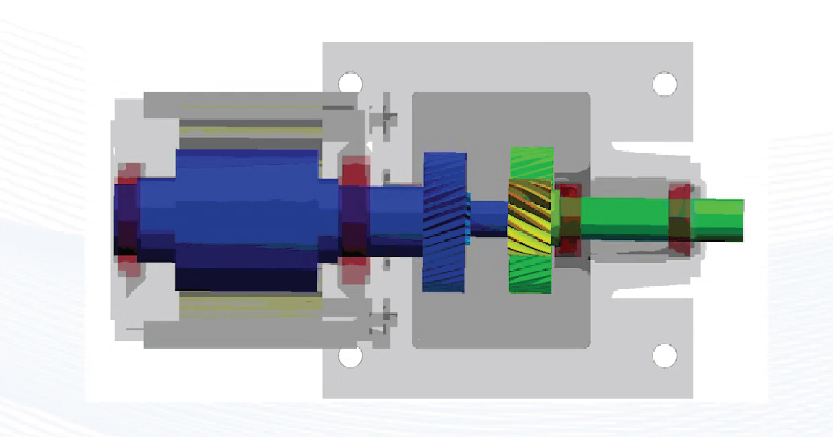

Rolling bearings are used in countless assemblies to support shafts. Often these are purchased parts, which for economic reasons can only be simulated in a very simplified way in the simulation process. With Rolling Bearing inside Ansys you can integrate high-precision bearings into your overall simulation within seconds – without expert knowledge.

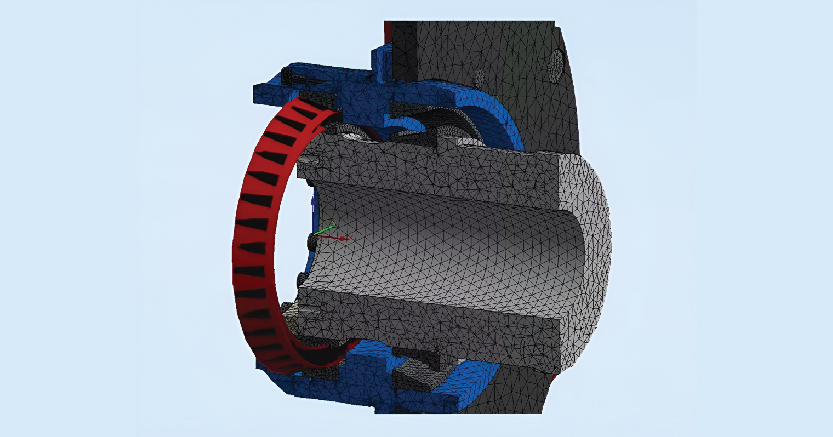

Utilize post-processing tools to analyze stress, strain, and displacement across the model, leveraging visualization techniques such as vector plots, streamline plots, and color-coded contour plots to understand the flow of forces. Focus on identifying force distributions and paths through critical components, joints, and supports for a comprehensive evaluation.