Fast strength evaluation with guideline-compliant verification according to the FKM standard. Full-surface strength verification of non-welded volume components according to FKM in compliance with guidelines. Strength verification of welds on shell and volume structures according to FKM in compliance with guidelines.

Identification of critical load cases through basic load case combinations involves analyzing different loading scenarios by combining simple individual load cases to determine the most critical conditions. This approach helps in identifying the worst-case load combinations that result in maximum stress or deformation, enabling engineers to focus on the most demanding operational conditions for design optimization and safety assessment.

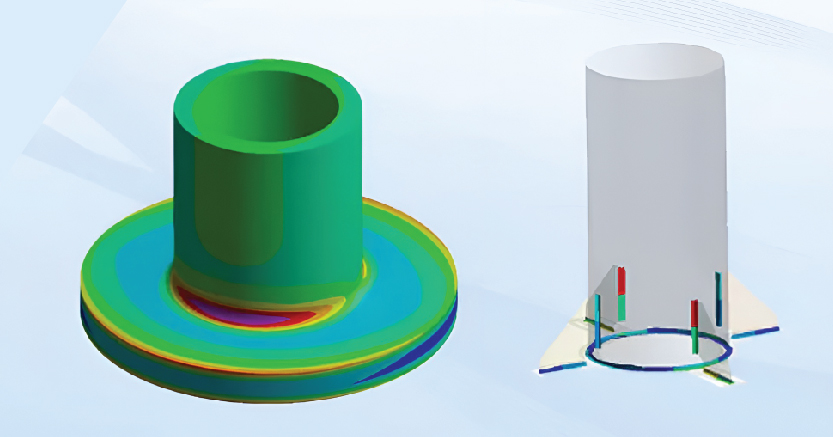

Full-surface strength verification according to FKM (Forschungskuratorium Maschinenbau) guidelines involves evaluating complex, user-defined solid components to ensure they meet established fatigue and static strength requirements. This method assesses all surface areas under various loading conditions, checking for compliance with FKM’s fatigue criteria, such as stress endurance limits, material properties, and loading cycles. The verification process includes detailed stress analysis, often using finite element simulation, to capture stress concentrations and load distributions across the entire component. By applying FKM criteria, engineers ensure that components meet rigorous standards for safety and durability, especially in high-stress or cyclically loaded environments. This is crucial for achieving reliable performance over a component’s intended lifespan.

Significant time savings due to simple user guidance result from intuitive, step-by-step workflows and user-friendly interfaces that streamline the simulation process. By guiding users through each stage—such as defining parameters, applying loads, and setting boundary conditions—the system minimizes complexity and eliminates the need for extensive training. This approach reduces errors, speeds up setup times, and allows users to quickly generate accurate results, ultimately enhancing overall productivity and efficiency in the design and evaluation process.

Direct display of the FKM stress ratio results in the FE model in ANSYS involves integrating the FKM guidelines for strength and fatigue analysis directly into the finite element (FE) simulation. After running the simulation, the FKM stress ratio is calculated and visually displayed on the FE model within ANSYS. This allows engineers to easily assess whether the component meets the required safety standards by comparing the calculated stress ratios to permissible limits. The direct visualization helps quickly identify areas that may need design adjustments, ensuring efficient and reliable evaluation of component strength and durability in real-world operating conditions.