This is where companies need a tool like, Granta Selector which does answer the above questions.

Granta Selector is a tool for optimizing your material choices, which not only has material properties

of metals, plastics, polymers, ceramics and various other classes of materials but also has features

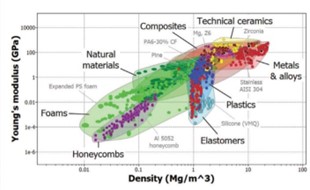

like search, plot and compare your choice of materials as shown in the pic.

Apart from the features mentioned above, Granta selector has: