Analisis Keselamatan Fungsional adalah pendekatan sistematis yang digunakan untuk mengidentifikasi, menilai, dan mengurangi risiko yang terkait dengan perilaku fungsional dari sistem yang kritis untuk keselamatan. Aspek utama dari analisis keselamatan fungsional mencakup identifikasi bahaya, penilaian risiko, dan implementasi langkah-langkah keselamatan untuk mengurangi kemungkinan dan tingkat keparahan kecelakaan dan cedera. Analisis keselamatan fungsional sangat penting untuk memastikan bahwa sistem yang kritis untuk keselamatan memenuhi tingkat integritas keselamatan (SIL) yang diperlukan dan mematuhi standar dan peraturan yang relevan, seperti ISO 26262, ARP 4761, ISO 21434, ISO 21448, IEC 61508, MIL-STD-882E.

Memastikan kepatuhan untuk Integritas Sistem yang Ditingkatkan

Kami menyediakan layanan konsultasi komprehensif untuk kepatuhan keselamatan dengan ISO 26262, ARP 4754/4761, ISO 21434, ISO 21448, IEC 61508, MIL-STD-882E.

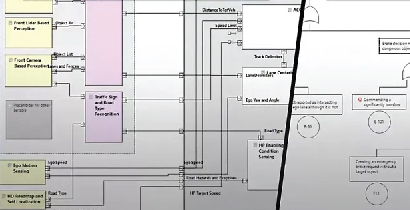

Kami menyediakan solusi untuk pengembangan arsitektur dasar dan pengembangan fungsionalitas tingkat atas sesuai dengan standar keselamatan untuk aplikasi yang kritis untuk keselamatan.

We specialize in providing top-notch solutions for Hazard Analysis and Risk Assessment (HARA) in compliance with ISO 26262.

HARA is a fundamental process in functional safety, involving the systematic identification of potential hazards, analysis of their causes and effects, and assessment of associated risks to safety-critical systems or products. This critical process ensures that safety-critical systems meet the required safety objectives and standards.

Mendefinisikan persyaratan kritis untuk keselamatan demi integritas sistem pada berbagai tingkat

Our solutions for Safety Goals and Requirements (SG & SR) modelling comply with ISO 26262. SG & SR modelling is a structured approach used throughout the development lifecycle of safety-critical systems. Safety goals represent high-level objectives related to system safety, such as minimizing the risk of harm to users, passengers, or the environment. These goals, derived from safety standards and hazard analysis, are complemented by safety requirements, which detail the functionality, performance, and constraints necessary to ensure safe operation. Safety requirements encompass various aspects such as functional safety, hardware safety, software safety, and operational safety.

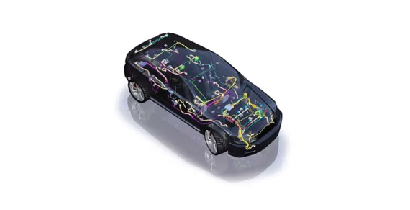

We offer comprehensive solutions for reliability analysis of all E/E systems, adhering to all relevant safety standards.

Reliability prediction for HW E/E components involves defining the failure modes of the component, distribution of the failure modes, and failure rate calculation using different failure rate catalogs tailored for various industries.

Our expertise extends to qualitative safety analysis, including Failure Mode and Effects Analysis (FMEA) and Failure Mode, Effects, and Criticality Analysis (FMECA), in compliance with all safety standards.

FMEA is a systematic approach to identify and mitigate potential failure modes within a system, product, or process, enhancing reliability and safety. FMECA goes a step further by assigning criticality rankings based on factors such as severity, system mission or function, and the likelihood of failure occurrence.

Analisis Penyebab Akar untuk Sistem Navigasi dengan menggunakan Analisis Pohon Kegagalan

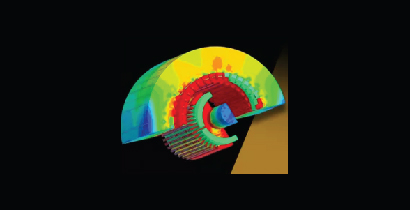

We provide advanced solutions for both qualitative and quantitative Fault Tree Analysis (FTA) in accordance with all safety standards. FTA is a deductive technique used to identify and analyze potential causes of system failures. It involves constructing a graphical representation called a fault tree to model relationships between various events and their potential outcomes, using logical gates such as AND, OR, and NOT to trace intermediate events leading to the top event.

Menilai keandalan komponen dan mode kegagalan untuk sistem yang kritis untuk keselamatan

Our solutions encompass Failure Modes, Effects, and Diagnostic Analysis (FMEDA) in compliance with ISO 26262. FMEDA is a systematic and quantitative method used to assess the reliability of complex systems. This analysis involves identifying potential failure modes, understanding their effects on system performance, and evaluating the effectiveness of diagnostic measures using SPFM and LFM techniques.

We offer solutions for various quantitative analyses, including Reliability Block Diagram (RBD) in compliance with all safety standards.

RBD is a graphical representation used to model and analyze the reliability of complex systems by depicting relationships between components or subsystems and their contribution to overall system reliability. The blocks are connected in series, parallel, or a combination of both, reflecting the system’s configuration and inter-component relationships.

Memahami disfungsi sistem atau Menganalisis ketergantungan suatu sistem.

Our services include Dependent Failure Analysis (DFA) in compliance with ISO 26262. DFA assesses the potential for failures within a system that may be influenced by other failures. This analysis helps engineers identify critical failure modes, assess their impact on system reliability and safety, and implement appropriate mitigation measures, ensuring the robustness and reliability of complex systems by addressing potential failure scenarios and their interdependencies proactively.